|

Anping Dade wire mesh Co.,Ltd

|

China manufacture heat preservation nails insulation nails

| Qty (Set/Sets) | Unit Price (0.04~0.09 USD) |

| 5000 - 9999 | 0.09 |

| 10000 - 14999 | 0.07 |

| 15000 + | 0.04 |

| Trade Term: | FOB,DAP |

| Payment Terms: | T/T,L/C,Paypal,Money Gram |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

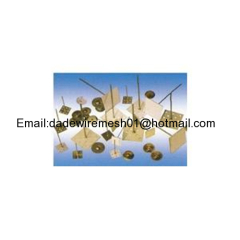

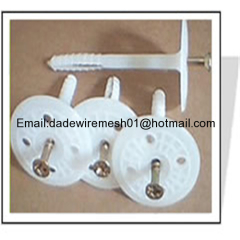

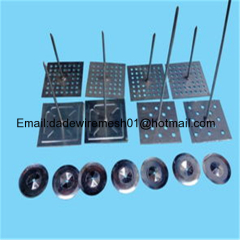

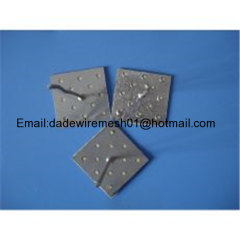

Heat preservation nail/insulation fixing nail

wall insulation engineering

architectural wall reinforcement

galvanized coat

Insulation plastic nail

China manufacture heat preservation nails insulation nails

Heat preservation nail is insulation board fixed on the wall of a kind of special engineering plastic bolts.Of exterior wall thermal insulation for heat preservation nail is the anchor pieces,widely used in building decoration,wall insulation anchorage.It is made of galvanized screw,nylon tube and round fixing sheet.

Details:

Material:low carbon steel,galvanized iron wire,plastic,etc.

Common Sizes:

8mm×62mm,8mm×82mm,8mm×102mm,8mm×122mm, 8mm×132mm,8mm×142mm.

Technique: Heat preservation nails is made by largely automatic injection-molding machine to produce.

Features: Nylon Stud with thermal insulation cap,effectively reduce the thermal conductivity, more energy saving.Anchor's own unique design,can effectively increase the efficiency of construction.

Specifications

model | bore diameter | tolerance | insulation material thickness | ||

bore diameter | anchor eye depth | anchor eye inside diameter | |||

8*60 | 8mm | 8.05-8.20 | 100mm | 8.05±10% | 25mm |

8*80 | 8mm | 8.05-8.20 | 120mm | 8.05±10% | 35-40mm |

8*100 | 8mm | 8.05-8.20 | 140mm | 8.05±10% | 55-60mm |

8*120 | 8mm | 8.05-8.20 | 160mm | 8.05±10% | 85-80mm |

8*140 | 8mm | 8.05-8.20 | 180mm | 8.05±10% | 90-95mm |

Application:

Heat preservation nail can be widely used in floor heating industry, power plants, petrochemical external wall insulation engineering,architectural wall reinforcement,noise, the construction industry,dill diameter 8-10. Available in different lengths fitting to the thickness of insulation board. We can make all kinds plug according to buyers demanding.Built-in solid-insulation nails,split-type up the nails,all-up of nails,nail with insulation (insulation corner network) combined with increased efficiency of 2-5times and reduce labor intensity.

Heat preservation nail products

Recommended assembly method

1. Operation at ambient temperatures between 15 and 25℃

2. Work surfaces should be clean and dry,free of dust,grease,oil and any other loose matter

3. Remove the protective release paper taking care not to touch the adhesive

4. Place the hanger in the required position and press the base against the surface to be insulated

5. Insulation can be impaled immediately and firmly locked with fastening clips but maximum strength of adherence is achieved after 24 hours

Packaging: